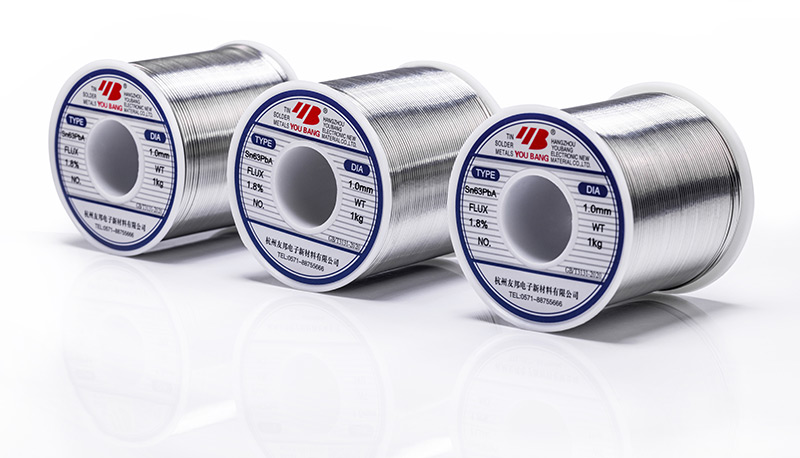

Solder Wire For Automatic Welding

Catalogue:Tin Lead Solder Wire

Product features:

The distribution of flux is uniform, with a deviation of ≤ 0.1%;

Uniform wire diameter, less likely to block the conduit;

Good wettability and fast soldering speed;

Low smoke and minimal splashing;

The solder joints are bright, with minimal residue after welding, and high insulation resistance between solder joints.

This product is suitable for robot automatic welding, compatible with various brands of automatic welding equipment, and also suitable for various welding methods such as drag welding and manual welding.

Information

This product uses special grade hydrogenated rosin and high-purity refined tin as the main raw materials, adopts a composite multi-element active flux formula, combines advanced production technology, strict quality control process, and perfect detection system, and is carefully developed to meet the needs of miniaturization and high-precision development of modern electronic products.

Product features:

The distribution of flux is uniform, with a deviation of ≤ 0.1%;

Uniform wire diameter, less likely to block the conduit;

Good wettability and fast soldering speed;

Low smoke and minimal splashing;

The solder joints are bright, with minimal residue after welding, and high insulation resistance between solder joints.

This product is suitable for robot automatic welding, compatible with various brands of automatic welding equipment, and also suitable for various welding methods such as drag welding and manual welding.

Model: Solder wire for automatic welding

Packaging specifications: 500g/roll (40 rolls/box), 1kg/roll (10 rolls/box)

Wire diameter specification: 0.3-3.0mm

Flux content: 1.8% (conventional), 1.5% (low content), 2.5% (high content), solid core

The flux content can be customized according to demand

Suggested welding temperature: 300 ℃~350 ℃, which needs to be adjusted appropriately according to the size of the welded part, welding process, and welding effect.

- Related products

Active Solder Wire

Product features:

The distribution of flux is uniform, with a deviation of ≤ 0.1%;

Good wettability and fast soldering speed;

Low smoke and minimal splashing;

The solder joints are bright, with minimal residue after welding, and high insulation resistance between solder joints.

This product is widely used for automatic and manual welding of electronics, instruments, household appliances, and printed boards.

Water Soluble Solder Wire

Product features:

Good wettability and fast soldering speed;

Low smoke and minimal splashing;

The solder joints are reliable and full;

The residue after welding can be cleaned with warm water.

This product is suitable for the water cleaning process in the assembly of modern electronic products, meeting the needs of the modern electronics industry for clean and green production.