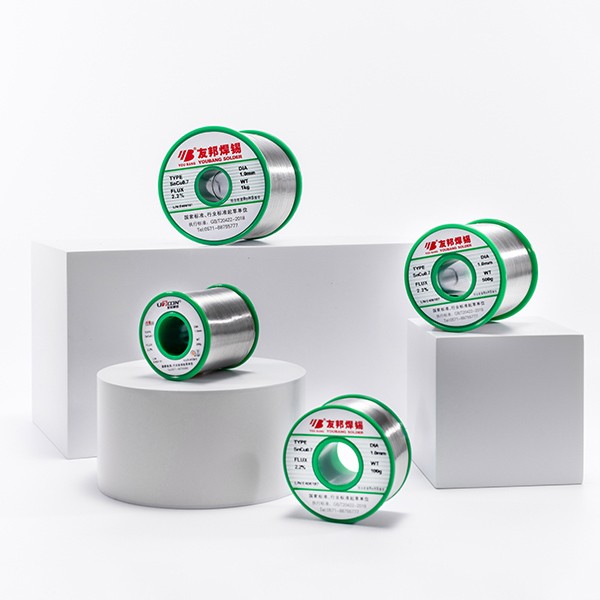

Lead-free Solder Wire

- Lead Free Active Solder Wire

- Lead Free Low Temperature Solder Wire

- Lead Free High Temperature Solder Wire

- Lead Free Aluminum Solder Wire

- Solder Wire For Lead Free Stainless Steel

- Lead Free Silver Solder Wire

- Lead Free And Halogen Free Solder Wire

- Lead Free Solder Wire For Automatic Soldering

- Lead Free Capacitors Solder Wire

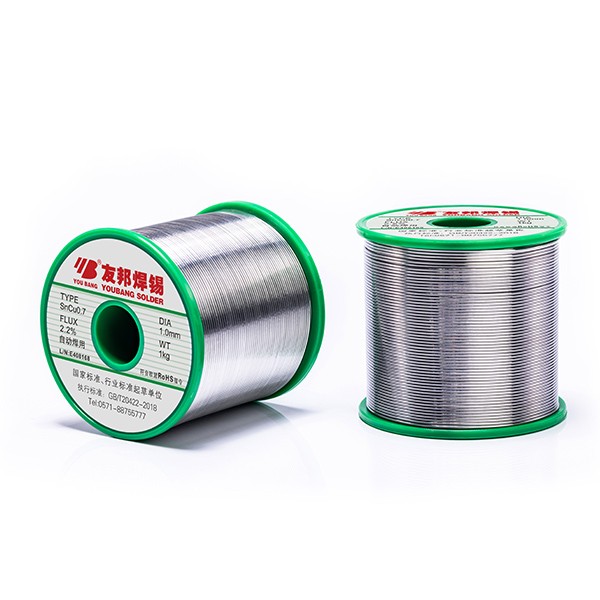

Lead Free Active Solder Wire

Product features:

The distribution of flux is uniform, with a deviation of ≤ 0.1%;

Good wettability and fast soldering speed;

Low smoke and minimal splashing;

The solder joints are bright, with minimal residue after welding, and high insulation resistance between solder joints.

This product is widely used for automatic and manual welding of electronics, instruments, household appliances, and printed boards.

Lead Free Low Temperature Solder Wire

Product features:

Low melting point (melting point: 139 ℃);

The flux is evenly distributed and has good wetting properties;

Low smoke and minimal splashing;

There is less residue after welding, and the insulation resistance between solder joints is high.

This product is suitable for welding thermal sensitive components, thermal overload protectors, fire alarms, temperature control components, air conditioning safety protectors, etc.

Lead Free High Temperature Solder Wire

Product features:

High melting point (melting point: 280-300 ℃), good high-temperature strength;

The flux is evenly distributed and has good wetting properties;

Low smoke and minimal splashing;

There is less residue after welding, and the insulation resistance between solder joints is high.

This product is suitable for welding processes with high melting points and welding electronic devices that need to work in high temperature environments.

Lead Free Aluminum Solder Wire

Product features:

Good wettability of aluminum surface;

The solder joints are reliable and full;

The residue after welding can be cleaned with warm water.

This product can directly achieve soft soldering connections on aluminum and aluminum, aluminum and copper materials, and is suitable for industries such as lighting, motors, transformers, etc.

Solder Wire For Lead Free Stainless Steel

Product features:

Good wettability of stainless steel surface;

The solder joints are reliable and full;

The residue after welding can be cleaned with warm water.

This product is suitable for direct soft soldering of different types of stainless steel surfaces, and can also be used for non structural soft soldering between various metals.

Lead Free Silver Solder Wire

Product features:

The distribution of flux is uniform, with a deviation of ≤ 0.1%;

Good wettability and fast soldering speed;

Low smoke and minimal splashing;

Reliable solder joints, minimal residue after welding, and high insulation resistance between solder joints;

Excellent conductivity and thermal conductivity.

This product is suitable for automatic and manual welding of electronics, instruments, household appliances, and printed circuit boards, especially for special applications that require high conductivity, thermal conductivity, and mechanical properties.

Lead Free And Halogen Free Solder Wire

Product features:

The distribution of flux is uniform, with a deviation of ≤ 0.1%;

Good wettability and fast soldering speed;

Low smoke and minimal splashing;

Reliable solder joints, minimal residue after welding, and high insulation resistance between solder joints;

The product complies with international halogen-free standards.

The application of this product has minimal environmental pollution and meets the dual requirements of environmental protection and high performance in modern electronic manufacturing, making it the preferred environmentally friendly welding material in the electronic manufacturing industry.

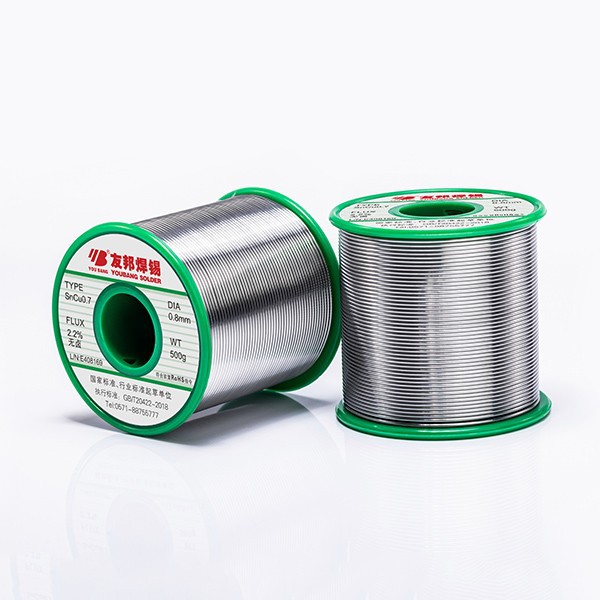

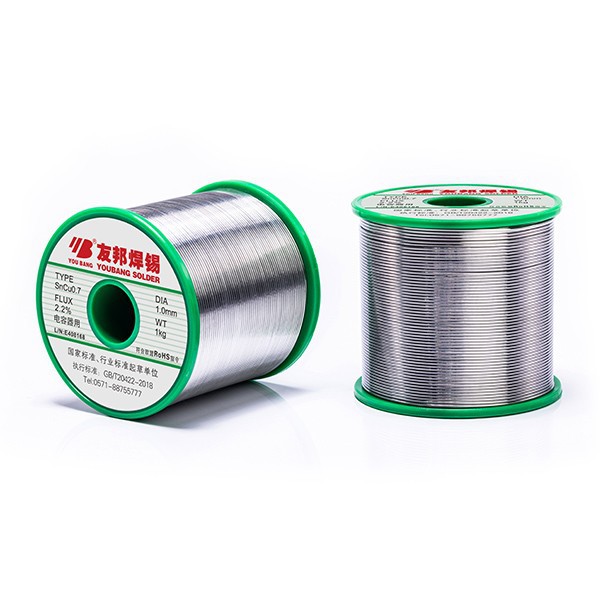

Lead Free Solder Wire For Automatic Soldering

Product features:

The distribution of flux is uniform, with a deviation of ≤ 0.1%;

Uniform wire diameter, less likely to block the conduit;

Good wettability and fast soldering speed;

Low smoke and minimal splashing;

The solder joints are bright, with minimal residue after welding, and high insulation resistance between solder joints.

This product is suitable for robot automatic welding, compatible with various brands of automatic welding equipment, and also suitable for various welding methods such as drag welding and manual welding.

Lead Free Capacitors Solder Wire

Product features:

The distribution of flux is uniform, with a deviation of ≤ 0.1%;

Excellent wettability and fast welding speed;

The welding points are beautiful and the welding quality is reliable.

This product is suitable for the capacitor manufacturing industry and can directly achieve soft soldering connection on the zinc coating and gold alloy coating on the end face of the capacitor. It is especially suitable for welding difficult to weld metal base materials, such as nickel plated parts, galvanized parts, Dumei wire, beryllium bronze, etc.