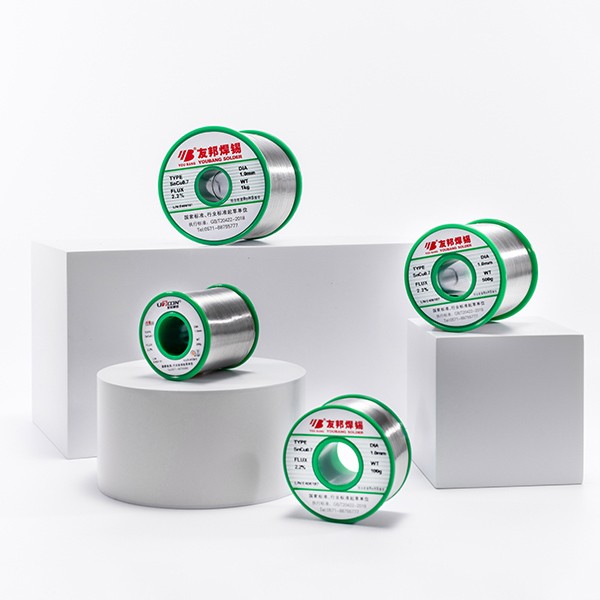

Lead Free Aluminum Solder Wire

Catalogue:Lead-free Solder Wire

Product features:

Good wettability of aluminum surface;

The solder joints are reliable and full;

The residue after welding can be cleaned with warm water.

This product can directly achieve soft soldering connections on aluminum and aluminum, aluminum and copper materials, and is suitable for industries such as lighting, motors, transformers, etc.

Information

In order to meet market demand and solve the difficulties of aluminum and aluminum enameled wire welding for a large number of users, our company introduced international advanced technology in 1996 and was the first in China to launch a series of products including aluminum specific solder wire, aluminum enameled wire specific solder wire, and environmentally friendly (lead-free) aluminum solder wire. The product complies with and exceeds the requirements of the EU RoHS directive.

Product features:

Good wettability of aluminum surface;

The solder joints are reliable and full;

The residue after welding can be cleaned with warm water.

This product can directly achieve soft soldering connections on aluminum and aluminum, aluminum and copper materials, and is suitable for industries such as lighting, motors, transformers, etc.

Model: SnCu0.7 (solder wire for lead-free aluminum)

Alloy composition: 99.3% tin, 0.7% copper

Melting point: 227 ℃

Packaging specifications: 100g/roll (80 rolls/box), 500g/roll (40 rolls/box), 1kg/roll (10 rolls/box)

Wire diameter specification: 0.5-12mm

Flux content: 2.2% (conventional)

Suggested welding temperature: 340 ℃~380 ℃, which needs to be adjusted appropriately according to the size of the welded part, welding process, and welding effect.

- Related products

Lead Free Active Solder Wire

Product features:

The distribution of flux is uniform, with a deviation of ≤ 0.1%;

Good wettability and fast soldering speed;

Low smoke and minimal splashing;

The solder joints are bright, with minimal residue after welding, and high insulation resistance between solder joints.

This product is widely used for automatic and manual welding of electronics, instruments, household appliances, and printed boards.

Solder Wire For Lead Free Stainless Steel

Product features:

Good wettability of stainless steel surface;

The solder joints are reliable and full;

The residue after welding can be cleaned with warm water.

This product is suitable for direct soft soldering of different types of stainless steel surfaces, and can also be used for non structural soft soldering between various metals.