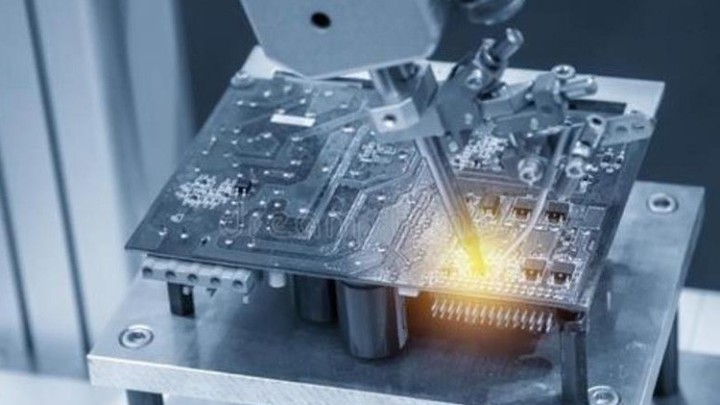

Application and Solution of Laser Soldering in the 3C Industry

3C products refer to a collective term for computers, communications, and consumer electronics. These types of products are usually small in size, so they are sometimes referred to as "3C small appliances".

The scope of the 3C industry is quite extensive, including laptops, various computer hardware and peripheral devices, communication including wireless communication devices, user terminal devices, switching devices, and transmission devices. In recent years, the mobile phone and telecommunications industries have been the main focus, while consumer electronics include digital cameras PDA、 Various digital products such as electronic dictionaries and portable drives belong to consumer electronics. The 3C industry has the global operational characteristics of short lifecycle, continuous cost reduction, and flexibility. With the pace of the digital age, 3C has gradually developed into a global emerging technology industry, which is the fastest growing and most frequently changing industry.

With the development of the 3C digital industry, 3C digital products are rapidly moving towards high integration and high precision. Due to the decreasing size, precision, and integration of internal components in products, higher processing requirements have been put forward for the appearance, deformation, and drawing force of internal structural components. In order to achieve perfect embedding and integration of each component, laser soldering machines can be used for CCM modules, CCM cameras, VCM motors, gold finger/FPC laser welding, and various wire welding, and high-precision laser welding processes must be used to compress parts.

Laser, as a high-precision, high-energy density, high brightness, green and clean processing method, can produce structures, equipment or systems with extreme scales, extreme precision, and extremely high performance, and has been widely used in the 3C field. In the manufacturing process of mobile phones, lasers can achieve 70% of the manufacturing process.

ULiLASER desktop laser constant temperature soldering machine features:

1. Laser processing has high precision, with a minimum spot diameter of 0.1mm, enabling the welding of micro pitch mounting devices and chip components.

2. Short term local heating has the least thermal impact on the substrate and surrounding components, and different heating specifications can be implemented according to the type of component leads to achieve consistent welding quality.

3. No soldering iron consumption, no need to replace the heater, achieving efficient and continuous operation.

4. Laser processing has high precision, with laser spots reaching micrometer level. Processing time/power program control ensures much higher processing accuracy than traditional soldering irons. Can be welded below 1mm.

5. Six coaxial optical paths, CCD positioning, WYSIWYG, no need for repeated correction of visual positioning.

6. Non contact processing, stress caused by non-contact welding, and no static electricity.

7. Laser is a green energy source, with the cleanest processing method, no consumables, simple maintenance, and easy operation;

When lead-free soldering, there should be no solder joint cracks.

Characteristics of ULiLASER closed-loop laser control system:

This software is applied in a series of processing and operating systems that require temperature detection during the welding process, such as laser constant temperature soldering and constant temperature plastic welding.

-Simple operation, powerful functions, and clear real-time feedback of working conditions on the operation interface;

-Can edit and process images in the display area of processing files;

-Provide system maintenance and upgrade services; Adopting coaxial camera with high positioning accuracy;

-Equipped with simulation processing function, it can detect problems with the processing route in advance and avoid erroneous processing;

-Automatic camera positioning through image recognition;

-Temperature control is optional and can be used in welding environments with strict humidity requirements;

-Welding parameters can be adjusted to adapt to various welding processing techniques.