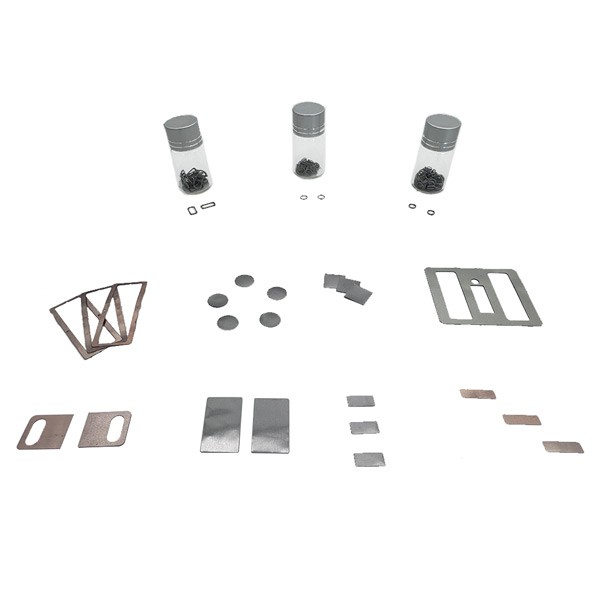

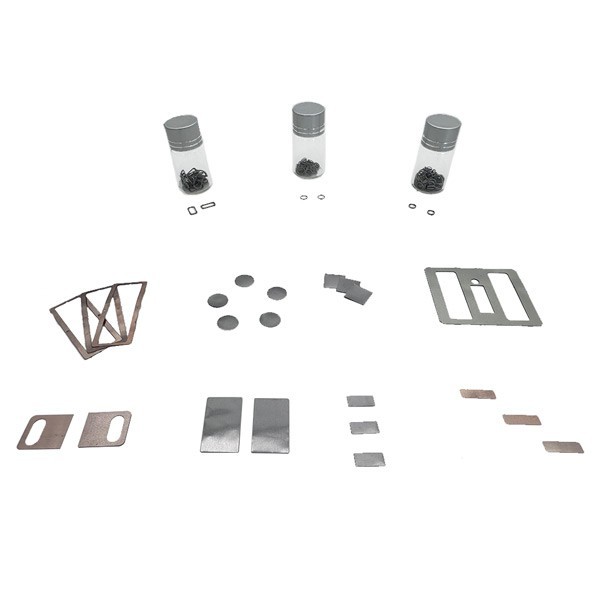

Pre formed solder customization

Catalogue:Solder Preforms

We can develop and produce pre formed solder materials with various alloy compositions, shapes, and sizes according to customer requirements.

Rectangular/Box shaped

Ripple sheet

Circular/Circular/U-shaped

Tin strip/foil

Punching ring/thin-walled ring

Ball shaped/granular

Tin pillar

alloy powder

Information

It is commonly used in situations where there are special requirements for the shape and quality of solder, and can be made into any shape and size to meet specific needs, providing precise solder dosage for connecting electronic devices. Common shapes include circular pads, disks, rectangles, and frames, and can also be made into different shapes and sizes to meet specific needs.

Under specific welding process conditions, the pre formed solder material,

It can achieve better welding results through fixed-point and quantitative methods,

Accurately control the dosage to ensure welding consistency.

It can achieve tape packaging for easy production and assembly,

Especially suitable for welding process requirements that cannot be achieved with ordinary solder materials.

- Related products

Solder Preforms

Product features:

Fixed point and quantitative feeding, precise control of dosage, ensuring welding consistency;

There is no spatter during the welding process, and there is very little residue after welding;

Support tape packaging to achieve automated mounting.

This product is suitable for precision welding and special welding processes that ordinary solder cannot meet.