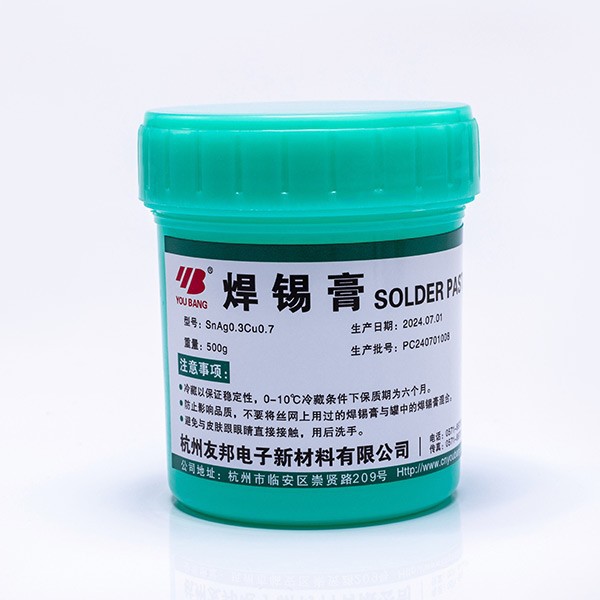

SnAg0.3Cu0.7 Solder Paste

Catalogue:Solder Paste

Product features:

The paste is uniform, odorless, and not layered;

Good printing performance, strong adhesion, and minimal collapse;

Good wettability, minimal splashing, fewer tin beads, and excellent welding performance;

Full solder joints, few voids, and high insulation resistance between solder joints;

Good conductivity and thermal conductivity.

This product is suitable for SMT surface mount and reflow soldering processes. Specially suitable for special applications with high requirements for conductivity, thermal conductivity, and mechanical properties.

Information

This product uses high-quality tin powder as the main raw material, and adopts formulas such as composite multi active agents and thixotropes. It is produced with advanced production technology, strict quality control processes, and a complete testing system. The product complies with and exceeds the requirements of the EU RoHS directive.

Product features:

The paste is uniform, odorless, and not layered;

Good printing performance, strong adhesion, and minimal collapse;

Good wettability, minimal splashing, fewer tin beads, and excellent welding performance;

Full solder joints, few voids, and high insulation resistance between solder joints;

Good conductivity and thermal conductivity.

This product is suitable for SMT surface mount and reflow soldering processes. Specially suitable for special applications with high requirements for conductivity, thermal conductivity, and mechanical properties.

Model: SnAg0.3Cu0.7 solder paste

SnAg0.3Cu0.7 Composition of solder paste alloy

| CHEMICAL ELEMENT | CHEMICAL COMPOSITION(wt.%) |

| Sn | margin |

| Ag | 0.3±0.1 |

| Cu | 0.7±0.2 |

| Bi | <0.06 |

| Sb | <0.10 |

| Zn | <0.001 |

| Pb | <0.07 |

| Ni | <0.01 |

| Fe | <0.02 |

| As | <0.03 |

| Al | <0.001 |

| Cd | <0.002 |

| Total impurities | <0.2 |

SnAg0.3Cu0.7 Physical properties of solder paste

| project | performance |

| melting point | 217~227℃ |

| flux content % | 12.2±0.2 |

| viscosity Pa.s | 200±30 |

| powder particle size μm | 15~25 |

| expansion rate % | >80% |

Packaging specification: 500g/can

instructions:

Refrigerate to ensure stability, with a shelf life of six months under 0-10 ℃ refrigeration conditions.

Before use, the solder paste must be allowed to return to room temperature, usually for at least 4 hours before printing.

To prevent any impact on quality, do not mix the solder paste used on the wire mesh with the solder paste in the can.

Avoid direct contact with skin and eyes, wash hands after use.

- Related products

SnAg3Cu0.5 Solder Paste

Product features:

The paste is uniform, odorless, and not layered;

Good printing performance, strong adhesion, and minimal collapse;

Good wettability, minimal splashing, fewer tin beads, and excellent welding performance;

Full solder joints, few voids, and high insulation resistance between solder joints;

Excellent conductivity and thermal conductivity.

This product is suitable for SMT surface mount and reflow soldering processes. Specially suitable for special applications with high requirements for conductivity, thermal conductivity, and mechanical properties.