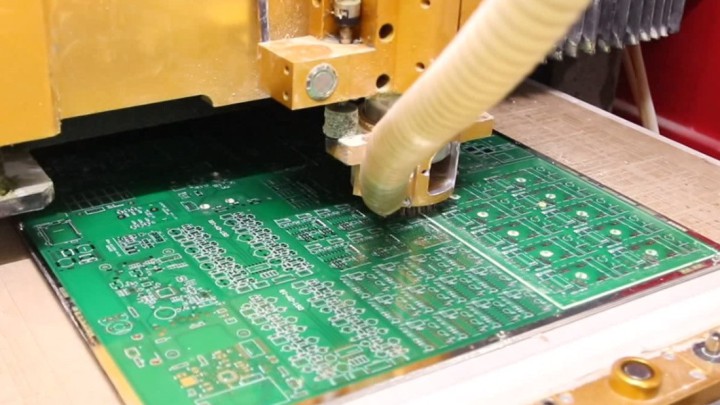

Laser soldering precision welding assists USB data cable processing

In the era of intelligence, USB data cables are essential for everything from smart home appliances, computers, and mobile phones to children's toys, Bluetooth earphones, and various popular internet games. With the continuous upgrading of terminal consumption, the structural design of consumer cable products is also constantly refreshed. The application of laser precision soldering technology has promoted the lean and automated production process of USB data cables, greatly improving their market value and enterprise efficiency.

Winding, stripping outer coating, copper wire separation, cutting aluminum foil, stripping core wire, welding, welding inspection, forming inner mold, semi-finished product testing, etc; A small USB data cable has extremely complex production processes. Welding, as one of the core processes, the quality and speed of welding affect the production efficiency and quality success or failure of the entire product.

The traditional welding method relies on manual positioning and slow welding speed, making it difficult to ensure accuracy and easily causing deformation and damage to the workpiece. Laser precision welding, as a new type of welding method, is an efficient and precise welding method that uses high-energy density laser beams as heat sources, without any mechanical pressure during the welding process. The heat affected area is small and will not cause deformation of the workpiece. The welding accuracy is very high, and the weld seam is fine, smooth, solid and firm.

With the increasing demand for high-frequency testing of consumer cables by market regulatory authorities, especially the quality of cable tail processing, it will directly affect the testing performance. In addition to safe charging and fast data transmission, the market terminal requires diversified upgrades such as multi head combination, scalability, and magnetic suction, which require USB data cables to be wear-resistant, durable, smooth charging and plugging, and even have certain waterproof functions, which traditional welding cannot achieve.

More refined and precise laser welding processes are being adopted by an increasing number of USB data cable manufacturers.

Characteristics of laser constant temperature soldering system

1. Laser processing has high precision, with a minimum spot diameter of 0.1mm, and can achieve micro pitch mounting of devices and chip components for welding.

2. Short term local heating has the least thermal impact on the substrate and surrounding components, and different heating specifications can be implemented according to the type of component leads to achieve consistent welding quality.

3. No consumption of soldering iron tips, no need to replace heaters, achieving efficient continuous operation.

4. Laser processing has high precision, with laser spots reaching micrometer level. Processing time/power program control ensures much higher processing accuracy than traditional soldering irons. Welding can be carried out in spaces below 1mm.

5. Multiple coaxial optical paths, CCD positioning, WYSIWYG, no need for repeated correction of visual positioning.

6. Non contact processing, no stress caused by contact welding, and no static electricity.

7. Laser is a green energy source, the cleanest processing method, no consumables, easy maintenance, and convenient operation;

When conducting lead-free soldering, there should be no solder joint cracks.