The indispensable laser soldering in the microelectronics industry

With the development of precision, thinness, shortening, miniaturization, and differentiation of electronic components, traditional processes are increasingly unable to meet the welding needs of ultra small electronic substrates and multi-layer point like parts. Laser soldering has gradually become a new technology to compensate for the shortcomings of traditional welding processes due to its technological advantages such as non-contact welding, no static electricity, and real-time quality control, and has been widely applied in the industry. With increasing market demands, laser soldering technology has also brought more development space to the electronics industry.

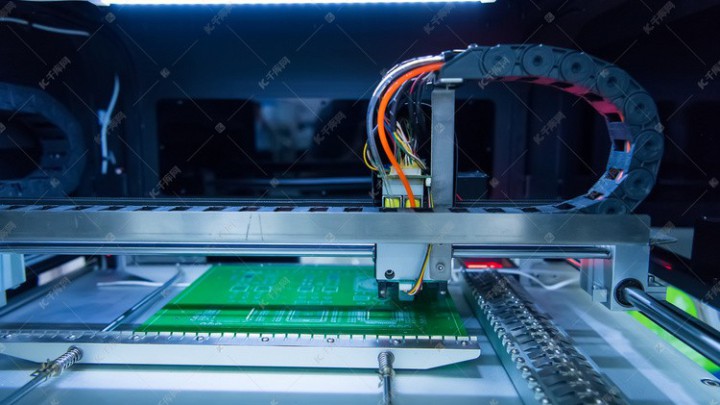

The principle of laser soldering is to use laser as a heating light source, transmit optical fibers and cooperate with the laser welding head to focus the laser on the welding area, convert the laser radiation energy into heat energy, melt the tin material, and complete the welding.

Laser welding is divided into solder paste, solder wire, and solder ball laser welding according to the state of the solder material. Compared to traditional soldering processes such as wave soldering, reflow soldering, and manual soldering with a soldering iron, the laser light source for laser soldering is mainly a semiconductor light source (808-980nm). Due to the near-infrared band of semiconductor light sources, they have good thermal effects, unique beam uniformity, and sustained laser energy. They have significant effects on uniform heating and rapid temperature rise of solder pads, high welding efficiency, precise control of welding positions, and good consistency of solder joints. They are very suitable for precision welding of small and micro electronic components, structurally complex circuit boards, and PCB boards.

The electronics industry is a national strategic development industry, and currently, the stock market space of the consumer electronics industry is still very large; On the one hand, personal computers, tablets, and smartphones have all begun to enter the competitive landscape of the Red Sea, which will bring about breakthroughs in technological innovation for their respective products, leading to new technological applications and process changes. In addition, with further technological innovation, a number of new products have emerged in the field of consumer electronics. Wearable devices such as smartwatches and smart bracelets AR/VR、 Consumer drones and other emerging consumer electronics products are developing rapidly.

Data source: Electronic Information Industry Federation

Laser soldering is suitable for materials

1. Laser solder paste welding

Laser solder paste welding is a laser welding technology that uses laser as a heat source to heat and melt solder paste. By coating solder paste on the solder pad and using laser heating to melt and solidify the solder paste, the operation is relatively simple. However, due to the fact that solder paste is composed of small particle solder beads, some of the solder beads are not completely melted at the edge of the laser spot due to low heat, resulting in residue and posing a risk of short circuit to the circuit board. Therefore, anti splash solder paste should be used as much as possible in laser solder paste welding to avoid short circuit caused by splashing solder beads.

Principle of Laser Solder Paste Welding

Laser solder paste welding is generally used for reinforcing and pre tinning micro precision parts and workpieces. In addition, it is also suitable for circuit conduction welding. The welding effect is very good for flexible circuit boards, such as plastic antenna bases, because they do not have complex circuits, good results can often be achieved through solder paste welding.

Application Case of UW Laser Solder Paste Welding

2. Laser Tin Wire Welding

After laser preheating of the welded part, the automatic wire feeding mechanism sends the tin wire to the designated position, and the laser melts the solder below the welded part to complete the welding.

Principle of Laser Tin Wire Welding

Laser wire feeding welding has the characteristics of compact structure and one-time operation, with full solder joints and good wetting properties with solder pads. It is particularly suitable for soldering integrated circuit boards and single electronic components such as PCB circuit boards, optical components, acoustic components, semiconductor refrigeration components, etc.